Trackwork

|

Basic trackwork is Peco 0-16.5 flexitrack. This was track recovered from a test-circuit I fitted around the loft when I had a workshop up there. The first points used were Peco 00 small radius points donated by a friend. The track-to-track distance meant that a very small section of track (loose rail) were required at the intersection, but it worked.

The track was laid on self-adhesive foam strip in an effort to reduce drumming noise through the thin ply base. However, this proved a major problem when pinning the track down as a minor roller-coaster was created. The track and foam was removed, and a traditional cork underlay fitted instead. |

The points worked OK for a while, but then electrical continuity became a bit of a problem. The decision was taken to replace them with homemade points. Although I had made 0-16.5 narrow gauge points in the past, I've never been that good. A pair were made, but it took a lot of fiddling before a serviceable cross-over was created. Working in a small space seems to amplify any glitches in running and the points are an area that will need careful monitoring.

The new live frogs required polarity switching, so another microswitch was fitted onto the point motor. |

Uncoupling magnets

|

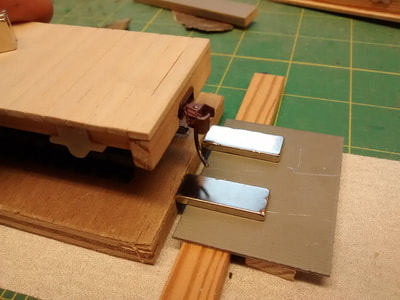

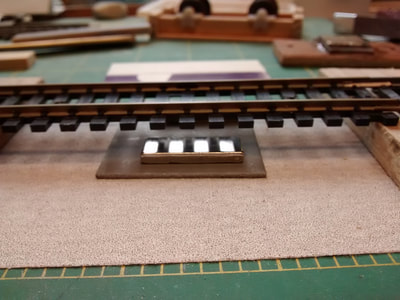

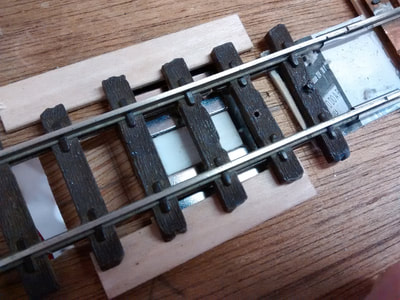

I've used Kadee couplers for most of my modelling life, having been introduced to them when I joined the Cottesmore group working on a 0-16.5mm layout that employed HO couplings. When, 30 years later, the group took-on the rebuilding of Worton Court, a section of the Cottesmore layout, we replaced the ceramic 'between-the-rails' magnets for under-track neodymium magnets. This took a lot of working out, as the magnetic fields are not like traditional magnets, but a satisfactory design was achieved. Once HO Kadees were chosen for BE, units were made and holes were cut for HO sized magnets i.e. for the same gauge track.

However, as the wagon principles developed, the slightly larger On3 couplers were adopted. It was during the testing of the first wagons that it became obvious that things were not right as the couplings didn't open properly. After careful reading of the instructions it was noted that wider O scale magnets were required to throw the larger knuckles open. It was back to the drawing board. |

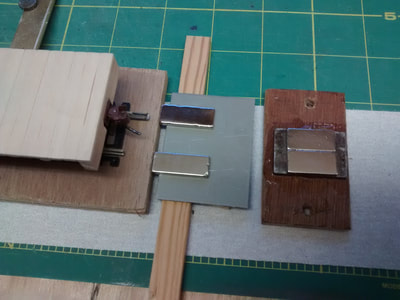

In the end, the redesign wasn't quite as onerous as feared. After making slightly larger ply base plates and steel keepers, experiments showed the same magnets could simply be moved apart and plastic spacers completed the adaptation. The optimum height was also determined through experimentation, and packers made to suit. Larger holes were cut on the ply baseboard and everything was OK again.

|