The Building

|

The first idea I had for the building was a crumbling brick shell with a 'down at heel' company, just scraping by. Over time, and after researching real and model examples, a more prosperous and smarter organisation developed.

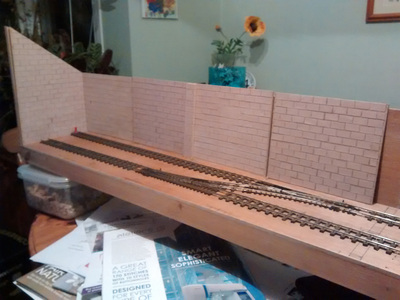

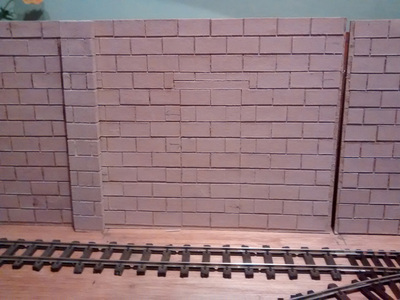

Walls - I had planned to have brickwork on the inside, and downloaded some bespoke brick paper sheets from http://paperbrick.co.uk/. However, the reason for working in this scale was to achieve detail, and the flat brickwork didn't 'cut-it'. I decided that individual bricks were out of the question, but as the engineering company became a more modern concern (in my estimation), a modern blockwork interior was more appropriate, and achievable. |

The walls were already broken down into bays, with piers for the main roof supports, so a sample panel was made up, then a sample pier. The surface was still 'hairy', but a coat of sealer and a sand down to remove the fluff before painting worked OK. However, the mortar joints still looked a bit too prominent, so filler was worked into them (universal finger tool), which was much better.

|

|

Roof - I initially sketched a steel truss frame, but didn't rule out a timber frame. Once I'd decided on the scale and was able to appreciate the width of the main area (narrower than expected) a simple / traditional timber structure was quite feasible. Large timber beams, with joists and a boarded soffit should provide the right amount of detail without becoming a major project of its own. While attending the Winter Ales Festival at the Derby Roundhouse, I found myself in the carriage room, looking up at the roof. Apart from the modern strip-lighting, it was what I had always envisaged. Just got to build it.

|

I then found an old spice rack in the loft that I made 30 years ago . It is made of obeche which will be perfect for the roof timbers. It has now been cut into the various sizes on a band saw, ready to assemble. The main roof will be 5mm Polyboard, with dummy boards glued on, like the blockwork. The beams and rafters will be made-up into frames and fitted to the soffit panel. The whole unit should then be in one removable section.

|

|

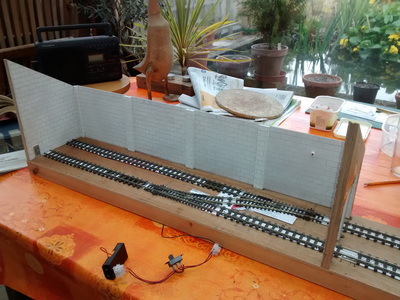

Floor - I'm still thinking about this. A completely flush concrete slab with tram rails would probably be best, but I've got standard O-16.5 and OO rails in plastic sleepers. I've seen some interesting prototypes, a few of which are shown below. I like them all! The main floor will be flush or almost flush with the rail top.

|

I'm tempted fill the track with plaster and then carve the flange ways out by hand, as the inner edge is often broken quite badly. However, I will consider the options and make a decision in due course. (Apologies to the sites these have come from for not being able to acknowledge them individually)

|

|

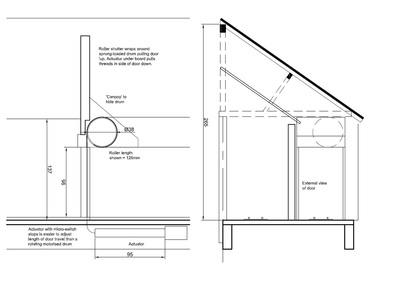

Doors - There are two doors - a roller shutter forming the main entry into the building and a pair of hinged doors into the workshop/store.

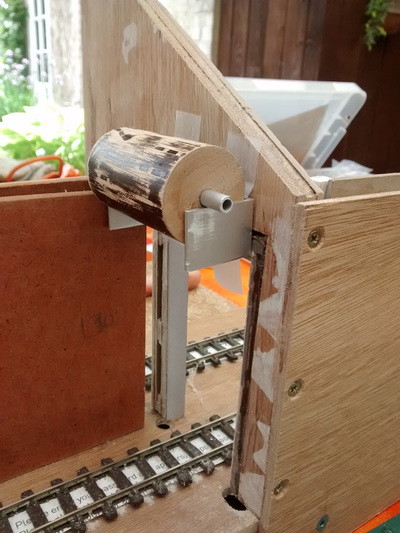

The idea of a working roller shutter door on the 'main line' was too good to miss. Complicated mechanisms were investigated on paper, but a much simpler system was eventually adopted. |

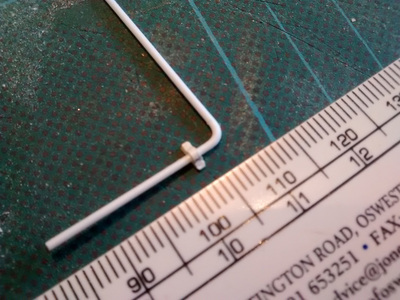

The hinged doors are still in abeyance, but drawings with a servo and arms have been prepared. Whether it becomes the final solution is anyone's guess!

|

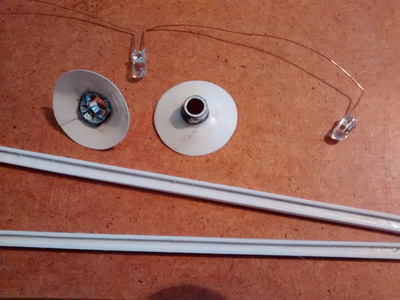

Details - At this scale, it should be possible to add a considerable amount of detail and I'm particularly keen to add electrical fittings such as lights, switches, conduits, fuse boxes etc. Once you start thinking of these items, it's amazing how many other details come to mind, such as fire alarms, smoke and security sensors, signage - both official and 'unofficial'. You just have to look around at any workplace for ideas. This should be a fun area to develop.

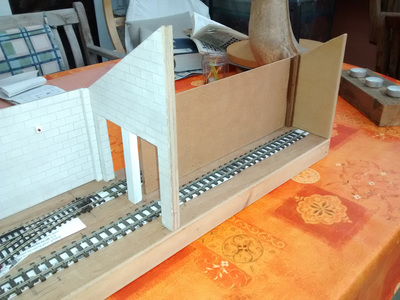

With the wall panels and piers in place, the building started to take shape. However, the workshop area is still has no fixed design, for walls or content. The initial idea is that the machinery will probably have to be 'off-stage' so there won't be much to see. However, the track might be shortened to facilitate a bench area, storage units, or a stripped-down vehicle etc. Appreciating the space won't come until it's been 'lived with' for a while.