Simplex 1

|

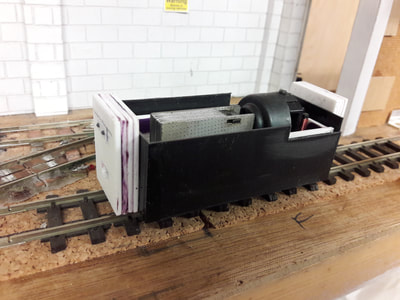

Another loco with its roots in 7mm, but this time it was a 7mm NG loco built on a Piko HO 0-4-0 chassis. It had been converted over 30 years ago and lay unused for a couple of decades. With the Worton Court layout almost ready for use, stock was required and the loco was brought out of retirement. The body had seen better days, so a full make-over was planned. Instead, after stripping, cleaning and lubricating the chassis, it became a Gn15 loco. The design was based on a mixture of versions found in the book on the history of Simplex.

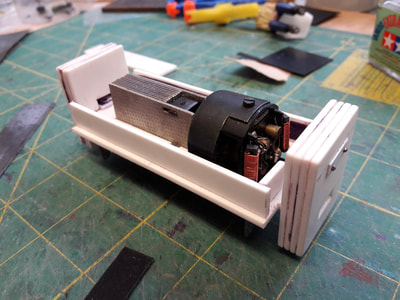

As usual, how to attach the body to the chassis was the first problem. The original body used a small screw in the top of the body into the plate between the vertical weights and the motor. However, this would be deep inside the new body and a different solution was required. Eventually, the screw idea was abandoned in favour of neodymium magnets. A pair of 30 x 10mm magnets were encased in plasticard and secured directly over the steel chassis and weight plates. The magnates are more than strong enough to allow the whole loco to be picked up by the body. |

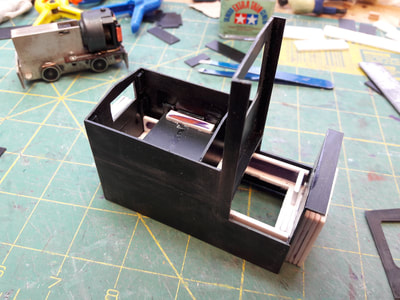

The On3 Kadee boxes are quite long and need to be taken into account at the design stage. However, I'd decided to keep the loco looking quite short/neat and a body extending over the Kadees wasn't going to achieve this. The answer was to hide the boxes in the extra weights provided to improve traction, which shortened the body significantly. The overhanging cab back found on one Simplex version also helped.

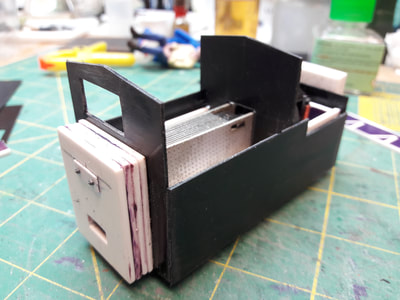

Bodywork was generally 1mm plasticard. It was decided to have the doors removable to enable paining, lights/wiring & other details to be added at a later date. This was achieved using 3 mm dia x 1mm thick neodymium magnets fixed to the door and door frame. Stiffening was required to the inside face of the doors to ensure a flush finish. After several trials, the grilles were eventually made from curtain netting sprayed black. Normally, I'd use a simple piece of brass rod bent to form a handle, but an article on 7mm detailing showed that a bit of hammer-work can create a more realistic handle. |

|

Final detailing and painting to follow...

|