Rolling stock 'principles'

|

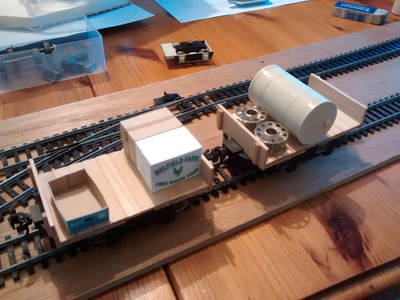

Size / width - Because of the confined space and the use of proprietary points, this was quite important to establish early on. The first items of stock tested on the embryonic layout were two 16mm Binnie skip chassis that had the wheels pushed in to 16.5mm gauge. These measured 52mm wide - clearly unstable for 15". However, 33mm wide Gn15 proprietary stock seemed too narrow and lacked some of the character of the former.

|

I did a quick exercise looking at various NG wagon drawings, trying to find a magic wagon-width to gauge ratio, but this was inconclusive as stock ranged from 23 - 42mm. However, it did lead me to dig out my O-16.5mm stock which included open wagons at 40-42mm wide. They looked convincing and, after some trial wagon drawings, 45mm was adopted as the principle width.

|

|

Wheels, axle boxes and couplings - So, here I was, basically repeating my O-16.5 stock with OO wheels/axle boxes and HO Kadee couplings, but at a much larger scale - and they didn't feel right - both were too small. As I tried to find a solution, all three elements conspired to run rings around me, which became quite frustrating. I had to investigate each individually, whist keeping an eye on how they all worked together.

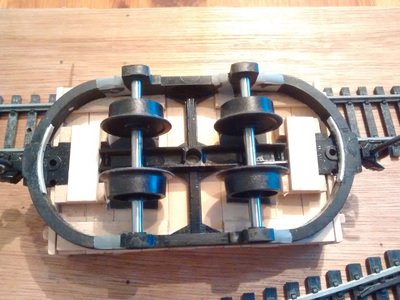

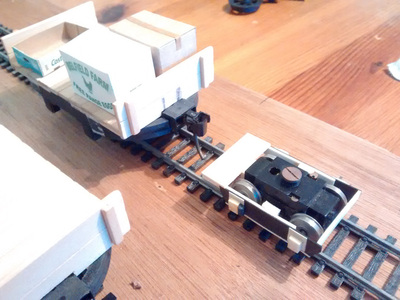

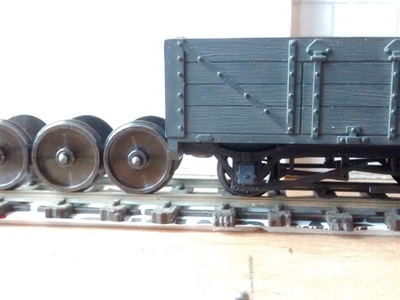

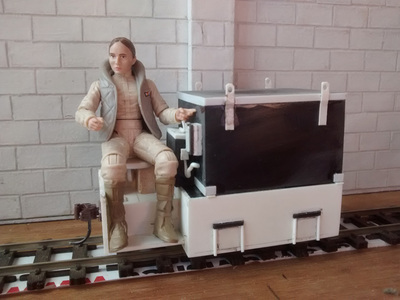

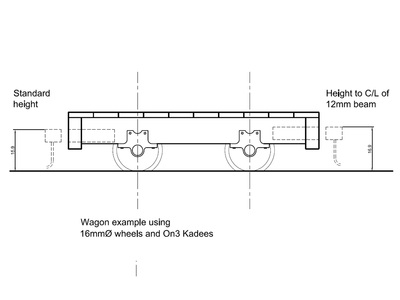

Wheels - First came the wheels. A friend gave me some 16mm dia. OO loco wheels. These were pushed onto some 2mm axles, fitted into some Cambrian, 16mm scale Talyllyn axle boxes, and made up into a small flat wagon. Initially pleased with the effect, searching found some 16mm dia. tender wheels made by Romford. Very nice wheels, but they required pin-point axle bearings. Axle boxes - Whilst the 16mm axle boxes initially looked OK, they did lift the wagon quite high, i.e. axle centre to solebar mounting was quite large. This became a major problem, when I tried to fit the HO couplings, which were far too low to fit in a typical buffer beam. A friend had had some success with resin and white-metal castings, so I drew my ideal box and planned to make a master and cast them myself. However, I was also aware of online 3D printing companies selling railway parts, but not the sort of boxes I was looking for. I investigated the process further, especially the type of drawing required. As I used AutoCAD, I was able to turn the drawing into a 3D solid figure and then export the file type required for printing. I then |

made contact with Chris Ward of C W Railways (www.cwrailways.com), who was very helpful and encouraging. I submitted my 3D drawing to Chris who confirmed my file was suitable and a sample run was produced. These are not cheap in small quantities, but I was very impressed with the results. I had planned to fit brass Romford bearing into my castings and would need to drill suitable holes, but it would be possible to incorporate something into future box designs.

Couplings - The 16mm flat wagons shown above have O gauge Kadee couplings, which I had intended to use on the SM32 layout but rejected for this layout, as they look enormous. After, reviewing the the HO scale Kadees on my O-16.5 stock, I initially decided they would be quite acceptable. However, a friend suggested I look at another Kadee product. Sitting between the standard gauge HO and O scale Kadee couplings is On3 (O scale narrow gauge). A couple of packets were sourced online and made-up. At the same time, their location in comparison to a 'reasonable' buffer beam was assessed by drawing. Whilst not in the centre of a 12mm buffer (10.6"), the position was more than acceptable. In fact, they would also fit within the depth of a 10mm (8.8") deep buffer. (Fitting them up into a cut-out in the bottom of the beam is my preference as a small bolt can be glued to the base of the wagon). They looked great. Not as fiddly as HO and not as big as O - a great solution. This, then, is to be the basis of future stock on the layout. Other problems may arise from the choices, but it looks like a good solution. |